Advantages of W20 three-phase low voltage motor:

Low noise, low vibration

High efficiency

Compatible with WEG frequency converter products

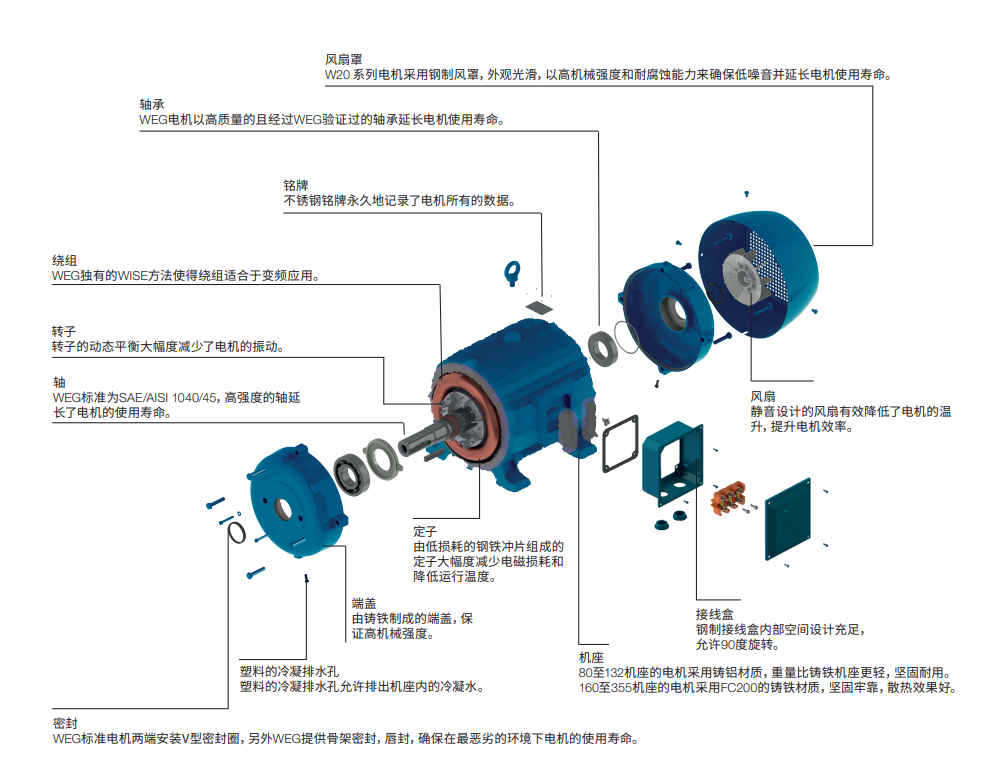

1、Aluminum alloy machine base is made of high quality cast aluminum, lighter than cast iron chassis, strong and durable. Aluminum housing is standard for motors with 80 to 132 frames. For easy installation, all models with frame size of 112M and above are equipped with lifting rings .

2、Like the base, the front and rear covers of the W20 motor are made of cast iron.The new design ensures long-term reliable operation of the motor over a wide range of ambient temperatures.

3、The fan cover is made of steel.

4、The W20 motor junction box is also made of steel junction box. In order to facilitate wiring, there is sufficient space inside the junction box, and it can be rotated 90°, so the installation is very flexible. The junction box hole is a Chinese standard threaded hole, and is equipped with a plastic stuffing cover.

5、The connecting wires are not only marked with IEC 60034-8 and GB 1971-2006 marks, but also equipped with designated wiring terminals. The W20 motors are equipped with glass-reinforced unsaturated polyester Bulk Molding Compound (BMC) binding posts.

6、WEG motors are equipped with ball bearings and grease drains on frames 225 and up. WEG cooperates with world-renowned bearing suppliers to ensure excellent motor performance and extended service life.

7、In frequency conversion applications, an axial fan (inner rotor motor 380V 50Hz) can be selected for forced cooling (90 to 355 machine bases) according to customer requirements. The position of the junction box of the axial fan is at the top by default (viewed from the shaft extension end). If you have special requirements for the position of the junction box of the axial fan, please contact the relevant sales staff.

| Voltage: | 220/380V(80-100machine base),380/660V(112-355 machine base) |

| Machine bases: | Aluminum shell 80-132 machine base(Iron shell option),Iron shell 160-355 base |

| Frequency: | 50HZ |

| EfficiencyGB18613-2020: | GB3(IE3),GB2(IE4) |

| Insulation class: | F |

| Ambient temperature: | -20℃-40℃ |

| Altitude: | 1000m |

| Service factor: | 1.0 |

| Continuous working system: | S1 |

Pumps, blower, crushers, conveyors, machine tools, milling applications, centrifugal testing machines, presses, elevators, looms, grinders, woodworking, cooling, packaging equipment, etc.

Follow Us